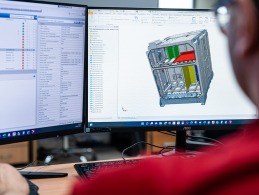

Design

Construction and technological department is responsible for complex preparation of production. It includes construction phase proceeded by FMEA analysis, valuation, and next, following customer's acceptance the process of introduction of a new product into production.

Introduction consists of preparation of documents, carrying out tests, designing production processes.

During design special impact is put on special processes that is coating, welding and gluing. Proper specialists prepare standards for production and suitable supervision schedule.

Metal sheet processing

Bending

- Bending brake Trumpf TruBend 5170, bending length 3000 mm

- Bending brake Trumpf TruBend 5320, bending length 4000 mm

- Bending brake Amada HFT130 pressure 130T, bending length 3000mm

- Bending brake Safan E-Brake pressure 50T, bending length 2050

- Bending brake Safan E-Brake Dual Drive pressure 300T, bending length 4000mm

- Bending brake Amada AE 2510 NT

CNC punching with punching press Amada AE 2510 NT

Laser cutting on the following machines

- Trumpf CO2 3040 table size 2000x4000

- Trumpf Fiber 5040 table size 2000x4000

Machining

Machining – 3 CNC axial milling machines

- Hartford Tornado – table size 1000x4000

- Hartford - table size 1600x1300

- Hartford - table size 600x800

- Dugart - table size 2000x800

Welding

Our company specializes in spot welding and welding with MIG, MAG and TIG method. These processes are certified acc. EN15085-2 “Welding of rail vehicles and their parts”, level CL1 and acc. EN 3834-2. Currently our staff includes 60 highly qualified welders.

Welding process is supervised by a welding supervision with IWE and IWS competences, whereas. NDT such as VT, PT, MT are also done internally.

Manual welding

Robotic-welding

Laser welding

Orbital welding

Assembly

Assembly and integration includes:

- simple mechanical assembly with i.e. screwing

- special process of riveting

- complex assembly of mechanical and electrical parts

Adhesive bonding

Adhesive bonding is certified acc. DIN6701, A2 level (Bonding of railway vehicles and their parts). Not only rubber or plastic parts are bonded, but also aluminum and steel parts with each other. We work of 1-part and multi-part glues.

The process is supervised by EAS Engineer (European Adhesive Specialist).

Stainless steel passivation

Stainless steel passivation (austenitic) carried out with the use of plunging method.

Size of baths 2500 x 800 x 700.

Powder and wet coating

Powder coating is carried out on half-automated line. Surface preparation is done with the use of chemical processes of cromodizing and passivation. Size of coating chamber:

- height - 1800 mm

- width - 1000 mm

- length - 3250 mm

Additionally the process of aluminium power coating was authorized by our final customer Deutsche Bahn and confirmed with special certificate.

Wet coating is carried out in the chamber sized:

- height – 4000 mm

- width – 2900 mm

- length – 6900 mm

Preparation of surface for coating is done with the use of grinding by shot blasting or corundum blasting. Company has chamber blasting machine, belt blasting machine and a chamber for manual blasting.

Quality control

The task of quality control apart from standard measurement of finished product is, first and foremost, supervision of production processes’ stability. With the use of such quality tools as 5Why, 8D or Ishikawa root causes of non-conformities are established, gathered and then grouped into categories according to certain criteria. Then using Pareto Analysis we implement corrective actions to eliminate those which are causing the most problems.

Each new product undergoes complex FAI process (First Article Inspection). On the basis of this critical parameters of products along with data collected during FMEA processes the scope, method and frequency of control is defined.

Quality control staff includes experienced quality engineers. We have own personnel for non-destructive welding tests, including VT (visual testing), PT (penetrant testing) and MT (magnetic testing) and for macro welds examinations as well. All the welded goods undergo detailed quality verification to meet the customer’s demand.

Logistics

- Just in Time (direct delivery to customer assembly line)

- Kitting

- Kanban

- Call-Off

- Consigment stock

- Rolling forecast

- Spare parts

- Returnable packaging